Italian agricultural machinery manufacturer Ocrim has partnered with Meyer Italy to enhance its product lineup with advanced optical sorting technology. The collaboration aims to deliver cutting-edge optical sorters designed to improve grain processing efficiency and quality for producers worldwide. This strategic alliance marks a significant step in integrating precision sorting solutions into Ocrim’s existing equipment offerings, reinforcing the company’s commitment to innovation in the grain industry.

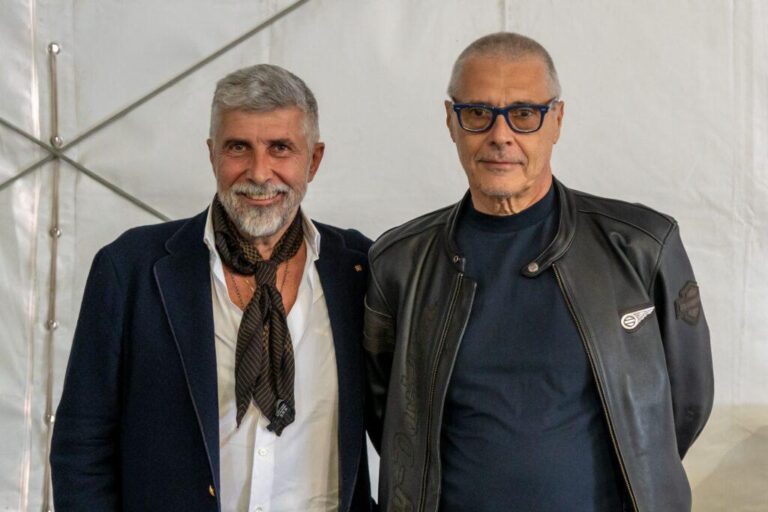

Ocrim and Meyer Italy Collaborate to Enhance Optical Sorting Technology

Ocrim, a leader in milling technology, has joined forces with Meyer Italy, a pioneer in advanced optical sorting machines, to revolutionize grain processing and quality control. This partnership focuses on integrating state-of-the-art sorting capabilities into Ocrim’s milling equipment, combining precision and efficiency to ensure producers receive only the highest-quality grain. By leveraging Meyer Italy’s sophisticated optical sensors and Ocrim’s engineering expertise, the collaboration aims to set new standards for accuracy in detecting and removing impurities from various grains.

Among the key benefits brought by this collaboration are:

- Enhanced Detection: Advanced cameras and software algorithms identify contaminants and defective kernels with unparalleled precision.

- Improved Throughput: Faster processing speeds without compromising sorting accuracy support higher production volumes.

- Customizable Solutions: Machines tailored to specific grain types and customer needs for optimized performance.

| Feature | Ocrim-Meyer Optical Sorters |

|---|---|

| Sorting Speed | Up to 6 tons per hour |

| Detection Accuracy | Over 99.7% |

| Grain Types Supported | Wheat, corn, barley, rice |

| Maintenance | Low, with self-diagnostic system |

Advancements in Sorting Efficiency and Accuracy for Grain Processing

Ocrim’s collaboration with Meyer Italy marks a significant leap forward in the precision and throughput of grain processing operations. By integrating cutting-edge optical sorting technology, the partners have streamlined the elimination of contaminants and defective grains, resulting in superior product quality. This system leverages multi-spectral cameras and artificial intelligence algorithms to distinguish subtle color and shape differences, achieving a sorting accuracy of over 99.5%. Such advancements not only reduce product losses but also enhance overall processing speed, enabling millers to meet growing market demands efficiently.

The combined technology offers versatile options tailored for various grain types, such as wheat, maize, and barley, accommodating fluctuating harvest conditions. Key features include:

- Real-time defect detection reducing manual inspection needs

- Minimal grain breakage preserving end-product integrity

- User-friendly interfaces optimizing operational control

- Energy-efficient designs lowering running costs

| Feature | Benefit | Impact |

|---|---|---|

| Multi-spectral Imaging | Enhanced Defect Identification | Reduces contamination rates by 30% |

| AI Sorting Algorithms | Optimizes Grain Selection | Improves sorting speed by 25% |

| Modular Design | Adaptable for Varied Grain Types | Increases operational flexibility |

Recommendations for Integrating Optical Sorters in Modern Milling Operations

To maximize the benefits of integrating optical sorters in milling operations, it is essential to align the technology with existing process workflows. Operators should begin by conducting a thorough evaluation of incoming grain quality and contamination levels to tailor the sorting parameters effectively. Regular calibration and maintenance of the optical sorters are crucial to maintain high sorting accuracy and minimize downtime. Additionally, comprehensive staff training ensures that the milling team can leverage system features fully and respond swiftly to any operational anomalies.

Emphasizing modularity can enhance scalability and adaptability in evolving production environments. Pairing optical sorters with real-time monitoring systems allows mills to track performance metrics and grain quality continuously, fostering proactive decision-making. Consider the following best practices for a seamless integration:

- Implement a pilot sorting phase to fine-tune settings without disrupting full-scale production

- Leverage data analytics from the sorter to optimize upstream and downstream processes

- Schedule routine inspections coordinated with mill maintenance cycles

- Foster collaboration between equipment suppliers and mill engineers for continuous improvement

| Factor | Benefit |

|---|---|

| Calibration Frequency | Maintains consistent accuracy |

| Operator Training | Enhances system responsiveness |

| Integration with Sensors | Enables real-time quality control |

| Modular Design | Allows flexible capacity adjustments |

To Conclude

The partnership between Ocrim and Meyer Italy marks a significant advancement in grain processing technology, combining Ocrim’s milling expertise with Meyer’s state-of-the-art optical sorting capabilities. As the collaboration moves forward, industry stakeholders can anticipate enhanced efficiency and quality control in grain sorting operations, reinforcing both companies’ commitment to innovation in the global grain sector. Further developments from this alliance are expected to shape the future of milling and sorting technologies in the coming years.