At the forefront of solar innovation, the recent PV CellTech USA conference provided a critical forum for industry leaders to dissect the challenges and opportunities shaping the future of photovoltaic technology. This year’s event saw intense focus on breakthroughs in perovskite research, persistent manufacturing bottlenecks, and the impact of evolving tariff policies. As stakeholders from across the solar supply chain convened, these themes emerged as dominant topics, underscoring the complex landscape confronting PV manufacturers and developers in the United States. The conversations and insights offered at PV CellTech USA highlight both the promise and hurdles facing the solar sector as it strives for greater efficiency, scale, and competitive advantage.

PV CellTech USA Spotlights Perovskite Innovations as Industry Game Changer

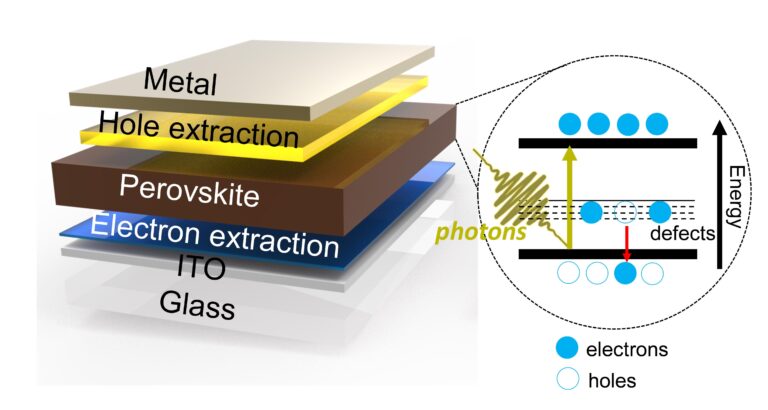

The spotlight at PV CellTech USA firmly shone on the rapid advancements surrounding perovskite solar cells, hailed as a potential revolutionary force in the photovoltaic sector. Industry experts highlighted breakthroughs in material stability and scalable fabrication techniques, signaling a clear pathway toward commercial viability. These innovations promise not only enhanced energy conversion efficiencies but also the potential to dramatically reduce production costs, challenging the dominance of traditional silicon-based technologies.

Despite the optimism around perovskites, discussions revealed persistent manufacturing bottlenecks that may slow widespread adoption. Supply chain constraints, coupled with ongoing tariff debates affecting imported components, continue to weigh heavily on project timelines and budgets. Key themes identified by attendees included:

- Material synthesis challenges restricting large-scale uniformity

- Integration of perovskites with existing silicon modules for tandem applications

- Tariff implications exacerbating price volatility for critical raw materials

| Factor | Impact | Industry Response |

|---|---|---|

| Perovskite Stability | Improved lifespan | New encapsulation methods |

| Manufacturing Speed | Current bottleneck | Process automation investments |

| Tariffs on Imports | Increased costs | Supply chain diversification |

Addressing Manufacturing Bottlenecks Key to Scaling Solar Production

As the solar industry accelerates towards mass deployment, overcoming manufacturing bottlenecks has emerged as a critical focus. Supply chain disruptions, limited availability of key materials, and the need for advanced automation technologies are hampering the pace of production scaling. Industry leaders emphasized that investing in flexible manufacturing lines and adopting innovative process controls will be vital to minimizing downtime and enhancing throughput rates. Without these improvements, the push to meet ambitious climate targets risks serious delays.

Key challenges highlighted include:

- Raw material scarcity, particularly for silicon wafers and rare earth elements

- Equipment lead times affected by global semiconductor shortages

- Skilled labor shortages impacting assembly speed and quality control

| Factor | Impact on Production | Suggested Solution |

|---|---|---|

| Material Supply | Delays in wafer procurement | Diversify suppliers, recycle scrap material |

| Equipment Availability | Long lead times for tools | Invest in local manufacturing of equipment |

| Labor Force | Inconsistent production quality | Training programs and automation |

Tariffs Pose Ongoing Challenges Fueling Calls for Policy Reform

Industry leaders at PV CellTech USA voiced growing frustration over the persistent impact of tariffs on the solar supply chain. These trade barriers not only inflate component costs but also contribute to significant delays in project timelines. Manufacturers highlighted how tariffs on imported materials force companies to reevaluate sourcing strategies, often at the expense of production efficiency and competitiveness in the global market. The ripple effects are particularly felt in the scaling of perovskite technologies, where cost volatility undermines investment confidence and slows commercial rollout.

Calls for comprehensive policy reform gained momentum, with stakeholders advocating for targeted adjustments to alleviate these constraints. Key talking points included:

- Eliminating tariffs on critical raw materials to reduce overheads and streamline manufacturing.

- Implementing support mechanisms that encourage domestic production and innovation in advanced PV cells.

- Establishing clearer trade guidelines to foster international collaboration and supply chain resilience.

| Impact Area | Current Challenge | Proposed Reform |

|---|---|---|

| Material Costs | 40% increase due to tariffs | Tariff exemptions for key imports |

| Production Delays | Lead times extended by 3-6 months | Streamlined customs procedures |

| Investment Climate | Hesitation amid market uncertainty | Incentives for domestic innovation |

Concluding Remarks

As the PV CellTech USA conference drew to a close, it was clear that the future of photovoltaic technology hinges on overcoming key challenges highlighted throughout the event. Perovskite advancements continue to promise transformative efficiency gains, yet scaling these innovations to commercial manufacturing remains a critical bottleneck. Simultaneously, the industry grapples with the ongoing impact of tariffs, which pose significant hurdles to global supply chains and market expansion. Stakeholders left the conference with a renewed focus on collaboration and innovation, signaling a pivotal moment for the solar sector as it strives to accelerate clean energy adoption in an increasingly complex landscape.