China’s Manufacturing Future: A Critical Evaluation of teh “Made in China 2025” Initiative

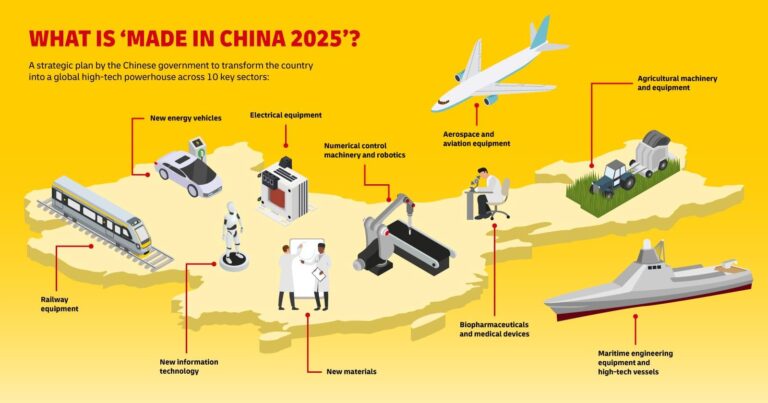

In recent times, China has emerged as a dominant force in global manufacturing, largely fueled by its ambitious “Made in China 2025” strategy. This initiative was designed to enhance the nationãs industrial prowess and lessen dependence on foreign technologies.The overarching goal was to position China at the forefront of advanced manufacturing sectors such as robotics, aerospace, and renewable energy. However, as this initiative nears its intended timeline, experts are closely examining both its successes and failures. This article explores the shortcomings of “Made in China 2025,” highlighting challenges encountered, responses from global competitors, and potential ramifications for China’s long-term economic aspirations. As the landscape of global manufacturing continues to shift rapidly, it is essential to understand these gaps within this strategic framework as China aims to redefine its role on the world stage.

Evaluating Challenges Facing china’s Manufacturing Vision

Despite china’s lofty ambitions for enhancing its manufacturing sector through “Made in China 2025,” several critical obstacles have surfaced that impede progress. firstly, a important reliance on foreign technology remains a major vulnerability for Chinese enterprises. Many local companies struggle with self-reliant innovation due to insufficient foundational research capabilities and growth resources; this makes them vulnerable to disruptions caused by supply chain issues or international tensions.

Secondly, stringent environmental regulations aimed at addressing pollution concerns have escalated operational costs for manufacturers who must invest heavily in compliance while striving to remain competitive.

The transition towards automation and advanced manufacturing technologies has also proven more challenging then anticipated due to several key factors:

- A lack of comprehensive workforce training programs that equip employees with skills necessary for high-tech roles.

- Resistance from conventional industries that are slow to modernize.

- Economic pressures diverting funds away from innovation towards immediate production needs.

| Challenge | Impact |

|---|---|

| Dependence on Foreign Technology | Lowers innovation potential and creates vulnerabilities. |

| Tight Environmental Regulations | Erodes competitiveness through increased costs. |

| Lack of Skilled workforce | Presents barriers against transitioning into advanced manufacturing sectors. |

Global Supply Chain Implications for ‘Made in China 2025’

The dynamics of global supply chains have experienced significant transformations recently that impact strategic initiatives like china’s industrial roadmap. The ambitious objectives outlined in “Made in China 2025,” which sought an upgrade of national manufacturing capabilities, now face hurdles stemming from changing trade policies, logistical challenges, and escalating geopolitical tensions. Industries reliant on smooth supply chain operations are grappling with tariffs and export restrictions amid a growing trend toward economic decouplingãfactors contributing to rising operational expenses that diminish the competitiveness of Chinese goods internationally.

The COVID-19 pandemic further exposed vulnerabilities tied to complex global networks; production delays highlighted inefficiencies within these systems. In response, manufacturers are adapting their strategies by investing more heavily into automation while reassessing sourcing decisionsãsome even opting for regionalized supply chains aimed at risk mitigation and enhanced resilience.

Key focus areas include:

- Pioneering Technological Advancements: Prioritizing AI (Artificial Intelligence) alongside IoT (Internet of Things) integration within production processes.

- Sustainable Practices:A noticeable shift towards environmentally friendly methodologies.

- Nurturing Local Sourcing:Aiming at reducing dependency on overseas suppliers.

Strategic Recommendations for Enhancing Technological Progress in China

If it aims to bolster its technological advancement strategy effectively,China must transition toward cultivating a sustainable ecosystem integrated globally rather than focusing solely inwardly on domestic capabilities. Essential recommendations include:

- Cultivating International Partnerships:Create alliances with leading technology firms worldwide along with academic institutions leveraging existing innovations.

- Diversifying R&D Investments: Allocate resources across various sectors beyond traditional manufacturing such as biotechnology or digital infrastructure.

- Fostering Entrepreneurship: Establish an habitat conducive for startups through incentives along with streamlined regulatory frameworks

- Revamping STEM Education: update curricula emphasizing practical applications coupled with critical thinking skills relevant todayãs tech landscape

- Promoting Lifelong Learning Initiatives: Develop continuous education programs ensuring workers stay adept amidst rapid advancements

- Encouraging Innovation via Incentives: Collaborate closely with industries creating scholarships/internships attracting young talent into tech fields

Tackling workforce skill gaps is equally vital; educational systems should evolve alongside emerging technological demands implementing strategies like:

Conclusion: Navigating Future Pathways Ahead

The ambitious vision behind ãMade In-China 2025ã seeks not only elevate but also secure leadership status within advanced technology/manufacturing realms yet faces considerable hurdles obstructing progress thus far . From over-dependence upon state support , geopolitical strains , unforeseen economic shifts – execution reveals misalignments against realities presented by fast-evolving markets . As reevaluation occurs , industry leaders/policymakers must adopt innovative approaches balancing state ambitions alongside market dynamics . Lessons learned could pivot future endeavors toward adaptability/collaboration ultimately reshaping roles played globally moving forward . The next few years will be crucial determining whether recalibrated trajectories can meet goals set nearly ten years ago .